National selection of top producer of

poison and fertilizer

in Iran

Omid International Conference

International Conferences Center

In Tehran

Omid Second International Conference

International Conferences Center

In Iran

Omid Third International Conference

International Conferences Center

In Iran

Omid Fourth International Exhibition

International Conferences Center

In Tehran

11th International Agricultural Industry

Exhibition

Machinery and related services

Second Specialized Agricultural Exhibition

The permanent location of

the Bustan fairs

11th International Agricultural Fair

Premier Booth

In Iran

Sixth specialized exhibition

Tehran Agricultural Agencies

In Iran

National Award for Top

Manufacturing Unit

In Iran-gazvin

First place

Safir Cup Tournament

In Winter

Top Team

Ramezan Cup Tournament

TehraniMoghadam

Third place

Safir First Futsal Cup Tournament

itcup

An overview of the principles and methods of mixing pesticides and chemical

Mixing pesticides and fertilizers is combining two or more pesticides or fertilizers together and spraying them on the target plant (pistachio tree, weed, etc.). Mixing pesticides or fertilizers is mainly to save time and money of spraying, while there are several pests and diseases in the garden or farm at the same time. Mixing two or more different pesticides together or mixing them with fertilizers (foliar fertilizers) or combining with adjuvants or additives is an action that is economical and reduces the cost, time and energy of the farmer and in some cases, it increases the effectiveness of pesticides (for example, adding soap to herbicides). Due to the high costs of spraying and foliar application separately, mixing pesticides and foliar fertilizers is an attractive task for many farmers. However, mixing of chemicals should be done with caution because some chemicals are incompatible with each other, resulting in tank deposition or disruption of any of the constituents of the mixture, and sometimes inefficiency of the mixture. This article describes the successful mixing of compounds and the creation of compatible mixing.

Advantages of mixing in the sprayer tank

The main advantage of mixing compounds in the sprayer tank is efficiency and convenience. It also allows the user to execute operational plans to act in a timely manner based on climatic conditions and the developmental stages of pests or crops. Other advantages of compatible mixing of toxins include the following:

- Improved control of some special pests

- Expand the range of target pest control

- Allow the simultaneous use of agricultural inputs with fertilizers, bio stimulants and plant growth regulators

- Reducing the frequency of application and consequently reducing the damage to crops and pesticide residues in the soil

- Reducing the possibility of resistance to pesticides with the simultaneous use of compounds with multiple effects

Basics of mixing fertilizers with pesticides

As mentioned, one of the ways to reduce the cost of using agricultural inputs (fertilizers and pesticides) is to mix them and spend energy and time together to consume them. The purpose of mixing is combining one or more fertilizers with one or more pesticides for using at the same time. The physical properties of the commercial formulation, how the product reacts to temperature, pH, water content and how the product is combined in common carriers for spraying (such as water, vegetable oils and fertilizers) are factors that must be considered in creating compatible mixing. For compatible mixing, it is necessary to pay attention to which compounds can be mixed with each other, and if this capability exists, how much will their consumption change in the mixing discussion. The first and best source for knowing the range of compatibility of materials is the label on their packaging. The recommendation that can be found common in the vast technical information of pesticides and fertilizers is that if mixed, it should be used on a small scale first and after seeing the result and not seeing a negative effect, it should be used on a larger scale. Some have strictly forbidden mixing with certain compounds. Some pesticides, including fungicides, are not suitable for mixing with nutrients and fertilizers in the spray tank. One of these fungicides is Fosetyl Aluminum. This fungicide is relatively acidic, so it may cause problems mixing with micronutrients. Of course, if the pH of the solution is neutral, the problem will be avoided to some extent. In some mixtures, despite the mixability of the composition, there is a possibility of damage to the sprayer tank. This has also been reported in the mixing of some fungicides with micronutrients.

Symptoms of iron deficiency can be seen in many greenhouse crops and ornamental species. These symptoms can be exacerbated by high soil or substrate moisture, high compaction of the root environment and poor ventilation. This problem is more pronounced in plants such as azaleas and some palms. Empirically, a wide range of iron chelates are compatible with fungicides and can be mixed with them. This feature can be used to solve iron-related nutritional problems and control fungal root diseases.

Urea, potassium nitrate and magnesium sulfate have been successfully mixed with most pesticides in the production of ornamental plants. Nitrogen and potassium are absorbed relatively quickly through the leaves of the plant. Plants with finer, softer leaves tend to absorb more nutrients than species with thicker leaves and waxy skin.

According to consumers' experience, some soluble materials, powders and granular materials mix well with nutrients; On the other hand, caution should be exercised when mixing liquid pesticides, especially pesticides containing petroleum and oily substances. As a general rule, do not mix more than three or four products of fertilizer and pesticide in one tank. According to several reports, the combination of the fungicide thiophanate methyl with nutrients has had satisfactory results. However, it is best to be cautious about the amount of nutrients consumed in this mixture. Because increasing the amount of substance does not necessarily increase the amount of absorption by the plant. Note that the dosage of each compound varies depending on the type of application, whether it is soil or foliar application. There are exceptions to mix for pesticides and fertilizers, which should be avoided. One of these exceptions is copper compounds. For example, fosetyl aluminum can be combined with some pesticides, but should not be mixed with copper and other metals. Also, do not try to mix hydrated lime or dolomite with a variety of fertilizers. This is because it can release too much ammonia. Mixing calcium nitrate with phosphorus fertilizers precipitates calcium phosphate. Also, the combination of calcium with sulfated fertilizers may cause some disorders. Mixing of copper compounds with biological and bacterial fertilizers and pesticides should also be avoided.

Fertilizer compounds such as urea, potassium nitrate, glucofonate chelates and magnesium sulfate can be combined in the fertilizer tank with a wide range of fungicides and insecticides. Most of the iron chelates can also be mixed in the fertilizer tank. In general, before mixing, carefully read the labels of pesticides and fertilizers and remember that if the amount of mixing is more than three, there is a possibility of errors and adverse effects.

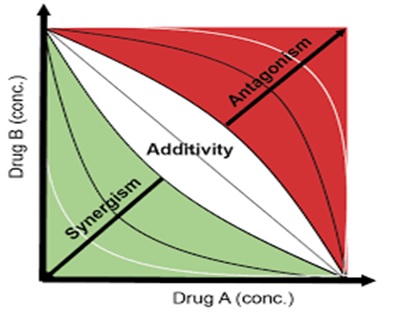

Mixing pesticides and fertilizers is not out of the four modes:

- Neutral or ineffective effect: This occurs when two pesticides or fertilizers are poured into the tank together and their spray on the trees does not have an aggravating or reducing effect. It is as if we have sprayed two pesticides or fertilizers separately. Many different fertilizers and pesticides have this effect or property (neutral effect) when sprayed together.

- Aggravating or synergistic effects: Synergistic effects occur when two or more different pesticides mixed together, have a much greater effect (in terms of pest control) than when sprayed on plants separately. Synergistic effects are beneficial to us because they help control pests better and may even reduce the use of pesticides. Some additives, such as some oils, may have exacerbating or synergistic effects on pesticides.

- Antagonistic effects: These effects are not desirable, meaning that if pesticides or fertilizers are mixed simultaneously inside the tank, their beneficial effects are less than when each is consumed separately. In addition to the reducing effects, antagonistic effects may cause phytotoxicity.

Additive effects: Additive effects usually do not occur when pesticides are mixed and are more related to the addition of substances called additives (additive + herbicide). For example, adding soaps or urea fertilizer to herbicides.

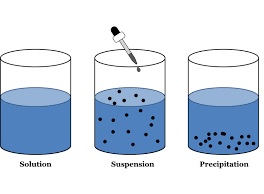

An important issue in the mixing of pesticides and fertilizers or other compounds is incompatibility. Incompatibility occurs when mixing two or more pesticides causes adverse effects. For example, a pesticide with an EC formulation cannot be mixed with a pesticide with a WP formulation. Or pesticides that have EC formulation cannot be mixed with fungicides or herbicides. It should also be avoided to mix ferrous sulfate with phenoxy herbicides such as 2.4.D, as this will clog the hoses and spray nozzles.

Complications of incompatibility may have two aspects: first, the physical aspect and second, the chemical aspect. Incompatibilities are usually more chemical. Chemical incompatibility is actually the chemical disintegration of pesticide molecules and fertilizers, but in physical incompatibility, most of the issue is physical. Such as sedimentation (jamming of hoses and nozzles, etc.) and crystallization, etc. In particular, the possibility of incompatibility of high-density fertilizers with pesticides is not out of the mind. In terms of a general classification, incompatibility creates four states: First, the reduction of the effect of pesticides or fertilizers, second, the deposition and entrapment of hoses and nozzles, third, phytotoxicity, which may cause various symptoms, and fourth, reduction of spraying efficiency, for example, heterogeneity in diameter or size of poison droplets. Disruption of two pesticides together or more is done to control two or more different pests at the same time and should be very careful in this case, and especially pay attention to the life cycle of the pests and considering the sensitive and vulnerable stage of the pest. For example, in the mixing of fenitrothion or consult at the beginning of the growing season. Fenitrothion is used to control cricked and pests inside clusters and seed pods, and fennel is used to control and repel the outbreak activity of pistachio psyllids in mid-spring, so mixing them only wastes time, cost and energy. In the case of herbicides, great care must be taken. Because in the case of mixing two herbicides together, the issue of phytotoxicity is not much discussed and it should be noted that the two herbicides do not have antagonistic effects on each other. For example, glyphosate or Randap cannot be mixed with Paraquate. Because the mechanism of action of the two are completely different, the simultaneous use reduces the effectiveness of each of the two herbicides. The quality of pesticides and fertilizers is also very important in mixing. It is possible that the incompatibility is due to the low quality of fertilizers and pesticides. It should be noted that many fertilizers are not miscible with pesticides and it is better to be tested at a low level first and then used at a large level. Fertilizer incompatibility testing with pesticides can be tested on several plants or trees. If there is an incompatibility between the pesticide and the fertilizer, the symptoms of incompatibility will appear on the plant within two to three days at the latest. Fertilizers with a high percentage of copper(Cu) or fertilizers that contain calcium(Ca) should be used with caution and should be sprayed alone. In the case of fertilizers with high humic acid, it should be noted that mixing them with potassium fertilizers with a high percentage of potash in the watering system or foliar application system may cause incompatibility and it is better not to mix. However, it is best to first consider the following before mixing any pesticides with fertilizer:

- Read pesticide or fertilizer labels carefully,

- Check the acidity or pH of the solution, as mixing may cause the pH to rise or fall too high, which can be solved by adding buffers.

- Before testing large-scale mixing, try to do it on a small scale, and if there is no problem in terms of compatibility, especially phtotoxicity, mix on a large scale.

- Care must be taken when mixing fertilizers with pesticides, as some fertilizers have a major impact on the pH of the tanker.

- Some toxins that have WP formulation, cannot be mixed with water-soluble pesticides and emulsifiers.

- Mixing high acidity fertilizers and pesticides with low acidity fertilizers and pesticides should be avoided.

- It is best to spray immediately after ensuring compatibility, as the passage of time, especially in alkaline waters, will cause the pesticides to decompose.

Regarding the mixing of pesticides and fertilizers, the important point is that it is better to mix the solution regularly during the spraying operation so as not to leave a deposit on the bottom of the tanker. Because sometimes it is observed that tankers do not use good mixers. The incompatibility is sometimes not clearly identifiable and has little apparent sign, and may be the only sign of a reduction in the effect of pesticides on pest control. In physical incompatibility during mixing, it is observed that the materials do not dissolve well, sediment is formed and sometimes they take on a layered state. In chemical incompatibility, raw materials mixed together lose their original properties and may be converted to other materials (even a new compound) and rupture occurs in the original compounds. Chemical incompatibilities are often not visible at all. Most of the chemical incompatibilities are due to the presence of surfactants in the input mixture of agrochemicals in the spray tank. For example, an oily substance added to the active ingredient of an herbicide can increase the penetration of the herbicide into the cuticle، but it can also affect the activity of the active herbicide and lead to phytotoxicity or leaching in the crops, while the active ingredient alone will not have such effects on the crop. The question is, why does incompatibility occur? The active ingredient in many pesticides may be solid, liquid, or gaseous. The active solids of a pesticide can also take many forms. A solid may in nature be crystalline or even waxy, which may be soluble or insoluble in water. The liquid active ingredient in a pesticide may also have a high or low molecular weight. This heterogeneity is very interesting and noteworthy, and pesticide manufacturers must first homogenize this heterogeneity as much as possible to arrive at a formulation that can be sprayed. In fact, this is the source of some incompatibilities. For this reason, the formulation of pesticides is done in various forms, including emulsions, suspensions, etc. Another important point is that many of the active compounds used in the structure of pesticides must be formulated in certain solvents, and this pure solvent must have a good solubility in water. Some incompatibilities are due to the fact that the solvent of the technical or main substance of the pesticide is not of good quality, and therefore the better the quality of the pesticide, the less incompatibility there is. As mentioned, acidity or pH is very important in the incompatibility of fertilizers and pesticides. When mixing pesticides and fertilizers, it is best to adjust the acidity of the solution using buffers as needed. Especially in the case of pesticides, the alkalinity of the pesticide solution will reduce the effect of pesticides (especially organophosphate toxins). Mixing herbicides with insecticides is not the right thing to do and is done in exceptional cases. As mentioned, mixing adjuvants with herbicides increases the effectiveness of herbicides. Often the active ingredient of a pesticide is not directly involved in the physical incompatibilities caused by mixing. For example, adding compounds with WDG formulations to spray tanks containing surfactants, oils, and some other products may cause physical incompatibility. Incompatibility when mixing is a costly phenomenon because it increases the cost and effort to clean the sprayer and on the other hand increases the cost of control due to the repetition of spraying programs.

It is recommended to reduce the ambiguous and possibly harmful effects of incompatible mixing:

- Maximum mixing should be done with only two poisons or combinations,

- Fertilizer compounds should be sprayed separately,

- If the number of pests is varied, it is enough to mix two items,

- Avoid adding compounds to the spray tank before the previous compounds have dissolved,

- Avoid mixing the compounds if there is not enough water in the sprayer tank,

- Avoid mixing the ingredients in the wrong order,

- Avoid mixing compounds with formulations that have not been tested before.

Mixing the compounds with excessive stirring causes foaming of water-soluble liquids, and conversely, too little stirring can cause the dry formulations to not dissolve.

When the air temperature is low, it should be noted that mixing is slower and as a result the mixing time will be longer. Caution should also be exercised when mixing with oily compounds or adjuvants.

General rules in mixing chemicals

The two solutions should never be mixed together. First add water to the first substance, then the second compound, and then the rest of the water.

As a rule, it is better to mix similar formulations. For example, wetable powder with wetable powder.

The order of mixing is as follows: first wetable powder, then dry fluid formulation and concentrate suspension and then water soluble formulations, surfactants, oil sprays and concentrate emulsions.

The following principles should be kept in mind when mixing:

- In general, compounds of acidic origin should not be mixed with substances of alkaline origin (lime or soap).

- The Bordeaux mixture mixes well with most ingredients except soap or lime.

- Oil sprays cannot be used with lime or lime-containing materials.

- Nicotine sulfate, lime sulfur, soap and non-soap oil emulsions and soap are contact insecticides and affect sucking insects.

- Mixtures of Bordeaux, Sulfur and Lime Sulfur are mainly fungicides and are used against fungal diseases.

- Very dilute solutions are usually ineffective, very concentrated solutions can be costly and cause plant burns. Diluting or concentrating any of the compounds in a mixture is usually done in the same way as diluting or concentrating Those compounds are done alone.

The following tips should be kept in mind when mixing:

Recommendation 1: Mix insecticides with acaricides, considering whether it is possible to mix or not.

Recommendation 2: Most acaricides cannot be mixed with fungicides

Recommendation 3: Although the possibility of miscibility is usually stated in the label of fertilizers, but as a precaution, due to the special conditions of foliar application in fertilizers, it is better to use them alone.

Recommendation 4: Considering the critical time of the plant for spraying during flowering and harvest time. Therefore, it is absolutely necessary to be careful when spraying at this time.

Recommendation5: Complications of incorrect spraying mix with jaundice, necrosis, leaf and fruit shedding, discoloration of leaves and fruits, growth of terminal buds, complications of indefinite and unilateral discoloration, etc. occur.

Recommendation6: Irrigation before foliar application mainly reduces the adverse effects of spraying.

As mentioned earlier, mixing materials regardless of their mixability can lead to serious problems such as reduced impact of raw materials, physical incompatibility between different materials, separation of mixture components, clogging of the spray system, foam, crystals and all. More importantly, phytotoxicity. In the mixing ground, all the factors that cause incompatibility must be carefully considered. Even when using a mixture that has already been proven to be miscible, incompatibilities may arise due to the quality of the water used. Some waters may contain iron, calcium, and other elements that contribute to chemical incompatibility. Some herbicides (amine salts) may react with calcium and magnesium in water to form insoluble salts, which reduces the effect of pesticides. Some newer insecticides affect the regulation of calcium ion concentrations in insects (calcium homeostasis). Mixing these insecticides with calcium fertilizers will reduce the effect of these insecticides. The stability of the mixture in the spray tank depends on the pH of the water. The optimum water acidity for pesticides should be 6 to 7. Acid or buffer should be used if the pH is outside this range.

Some chemicals are not miscible due to physical incompatibility. Physical incompatibility can be due to incorrect mixing, insufficient stirring or lack of stable emulsifier in some EC formulations. Mixtures of these chemicals require vigorous stirring and the addition of Surface active ingredients (surfactants, chemicals, etc.). Otherwise sediment will form or become a two-phase mixture. Mixing the WP formulation with the EC in case of insufficient stirring can form a soft paste with an oily layer that floats on top of the spray tank. In the event of a physical incompatibility, the mixture may become a separate layer (oil and water) and the solids may settle faster than normal. Physical incompatibility can be costly in terms of cleaning solids and hard deposits in the spray tank, nozzles and spray hoses, and in severe cases if the equipment is not thoroughly cleaned can cause serious damage to agricultural products.

Particular attention should be paid to mixing EC formulations with liquid fertilizers. Sometimes products that mix well and can be mixed should not actually be consumed together, as the effect of mixing the two ingredients may differ from the effect of consuming each of these ingredients alone. Chemical incompatibility due to improper mixing has a negative effect on the quality of adsorption and contact of mixed inputs with the plant surface. It can also cause plant burns. Sometimes it also reduces the impact of the input. Therefore, it causes the need to repeat the pesticide and while reducing yield, it also damages the product.

One of the most common mixing problems with WDG and WP formulations in the tank occurs when oil-based compounds or oil additives are added to the sprayer tank before adding compounds with solid formulations. Because oils are less concentrated than water, the oil remains on the liquid surface, so when a solid formulation is added to the tank, you first encounter a layer of oil that covers the solid formulation. This oily coating prevents water from reaching the particles of the solid formulation and limits its solubility. As a result, the solid formulation cannot be decomposed into primary particles, which leads to larger particles in the tank and hoses, which can clog the nozzles and filters. In addition, the amount of water used when preparing the mix in the tank is a very important factor. Using a small amount of water may cause solids to accumulate or gel to form. The more water available to disperse or dissolve the products, the less likely it is that the product will settle to the bottom of the sprayer.

Also, before adding a compound, the previous compounds must be stirred in the tank for a certain period of time. Adding the compounds immediately in a row may lead to physical incompatibility. It should also be noted that when a compound is dispersed in the carrier, it does not mean complete dissolution of that compound. Mixed compounds never dissolve immediately in the carrier, especially when cold water is used as the carrier. Also, the tank mixture must be stirred regularly, otherwise they will settle over time. Although excessive stirring can lead to problems such as foaming, foaming is a problem, especially for WP, WDG and WG formulations. Because solid formulations remain on the floor and only slightly wet. Since these compounds are not in contact with enough water, they do not disperse completely and settle to the bottom of the tank. The use of rotary agitator and anti-foaming agent in the early stages of mixing, causes proper and foamless dispersion of mixed compounds. Anti-drifting agents must also be added often in the last step.

Water and some liquid fertilizers are two common carriers used to prepare pesticides in the spray tank. The only similarity between liquid water and fertilizer is that they are liquid. Water is a better carrier for mixing in the sprayer tank and most of the pesticides are diluted with water. Liquid fertilizers are electrolyte solutions that contain charged ions such as sodium, potassium, chlorine, calcium, phosphate, and ammonia. As a result, they have less water molecules available for dissolution to dissolve pesticides. In addition, the salts in liquid fertilizers can react with the compounds in the formulation of pesticides and cause incompatibility.

Water temperature can also affect the degree of dissolution of pesticides, dispersion, emulsifiability and lubrication of pesticides. In general, materials dissolve more in warmer water than in cold water. Solid formulations and liquid suspensions also take longer to disperse in cold water. When mixing pesticides in cold water, first mix each mixture in the tank for at least three to five minutes, then add the next compound to the mixture. Cold water also causes problems for concentrated emulsions and water-soluble packages. In cold water, these formulations form gels that are difficult to disperse and as a result the active ingredient is evenly distributed in the tank.

It should be noted that the accompanying ingredients in the formulations of the compounds may be changed periodically by the manufacturers. Therefore, the mere fact that a consumer has mixed a mixture for example for 15 years without any problem is not a sufficient reason for compatibility, and the new formulation and technology may lead to different reactions than we expected.

Mixing products with oil base (suspensions and emulsions) before other formulations causes the interaction of petroleum products and other compounds, especially compounds in solid formulations. Therefore, the correct order of mixing is very important.

It should be noted that antifoams and pH regulators are not included in the mixing protocols, and the order in which they are added usually indicates the label of these compounds. Anti-foams neutralize the foam during the mixing process. Never add the entire amount of foam to the sprayer tank. Instead, do this step by step and add some anti-foam at the end of the mixing process.

When using liquid fertilizer as a carrier for mixing in the spray tank, first read all the labels of the compounds carefully. Then, based on the information on the label, determine the optimal water pH, the effect of hard water, the need to add auxiliaries such as surfactants or oils. Shake the ingredients well before pouring them into the tank so that the active and inert ingredients are thoroughly mixed. Fill the sprayer tank 50 to 75% of the desired fertilizer volume and never pour pesticide compounds directly into the tank. Then add the remaining fertilizer to the sprayer and check for signs of incompatibility in the mixture and stir the mixture until use.

Prevent incompatibility problems in mixing

Mixing two or more herbicides in a spray tank is more common than mixing other pesticides. Herbicides and fungicides are very uncommon due to the need for treatment at different times and the need to use special nozzles with different pressures. When two or more pesticides are mixed properly, it will not adversely affect the toxicity, physical properties and health of the plant. However, in case of incompatibility due to mixing, side effects such as cytotoxicity, reduced activity of one or more active substances, foaming or sludge formation in the tank will be caused. Therefore, in order to ensure consistent mixing, the compatibility test must be performed in a limited way. Some problems due to mixing incompatibilities are irreversible, but in some cases, it is possible to solve the problems caused by incompatibilities by adding more water or adding compatible materials, pH adjusters or non-ionic detergents and surfactants. You can contact the dealer or manufacturer of the ingredients to evaluate the available options. If the incompatibility problem is not only related to the tank but also to the nozzles, pumps and hoses, the contents of the sprayer should be completely discarded to ensure that all materials come out of the equipment and will not be caused problems in the future. Since mixing without knowledge and without pre-testing puts agricultural products at great risk and in many cases it is not possible to improve the situation, so it is necessary that mixing is done with awareness and planning and previously tested at a limited level.

Farmers usually combine different types of fertilizers to reduce costs, regardless of their properties such as purity, solubility, incompatibility or the benefits of some materials such as activators, buffers, chelates, etc. Adding nitrogen fertilizers in the form of urea and ammonium to the pesticide tanker may cause high pH and incompatibility with droplets of pesticides. On the other hand, adding phosphorus fertilizers in the form of phosphate or phosphoric acid to the pesticide tanker creates a mixture with low pH.

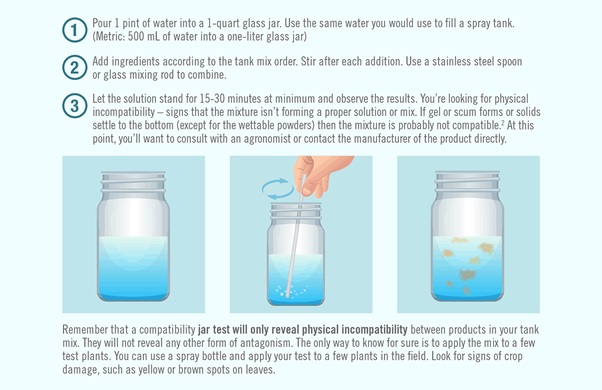

It is very important to add the ingredients to the spraying tank according to the order and it should be in the order mentioned in the label of pesticides or fertilizers. In some cases, whether the materials are physically compatible will depend on the order in which they are dissolved in the pesticide tank. This is especially true of WP pesticides. A mistake in the mixing arrangement may lead to incomplete dissolution as well as impede the uniform distribution of the pesticide in the spray tank. Usually on the label of toxins provide detailed methods for mixing materials. If this information is not available, a mixing test must be performed. Miscibility testing is performed by different methods and purposes in a small container before mixing the materials in the poison tank. Chemical compatibility cannot be determined by simply mixing the products in a simple test such as the one mentioned earlier. Some products can be easily mixed together, but can cause antagonism, resulting in reduced toxin function. Or it may be synergistic and increase the effectiveness of toxins. Crop damage can occur when several pesticides or fertilizers are mixed together. Therefore, the label of toxins and the mixing test can be the best guide for mixing the desired compounds. Also do not forget to consult with experienced professionals.

General principles of mixing pesticides in the spray tank

Always use pesticide labels to make sure they are miscible with other pesticides and fertilizers or to learn about possible methods. But such information is not listed on the toxin label. So, Use the following method:

- Prepare a medium clean container, such as a glass bottle. Use the same water that you use when making the base mix. Fill the container halfway with water and then add each of the mixture components to the container in proportion that will later be poured into the main tank. Of course, add wetting powders (WP) and other water-soluble powder and granule formulations (WDG). Then mix the solution thoroughly and add the rest of the water. Liquid materials such as soluble formulations, surfactants and colloidal suspensions and emulsifiers are added at the end.

Therefore, the order of adding pesticides based on the formulation is as follows:

WP- DF-WDG-F-FL-ME-EC-S-SP

- Then add oils or surfactants

- hake the container well. Let the mixture stand for 15 minutes and check the heat again. If the sides of the container are heated, the materials may have chemically reacted with each other, which means that the materials should not be mixed together. Also, pesticides should not be bilayer, discolored and have crystalline particles. If after this period the resulting mixture suffers from sediment, disintegration of components, jelly and the like, it can be concluded that the mixed materials cannot be mixed and if none of these cases occur, the pesticides can be mixed with each other.

- If excess material is found on the surface of the mixture or sediment forms at the bottom of the container (except for WP formulations), the materials may not be compatible with each other.

Finally, if there are no signs of incompatibility, test the mixture on a small surface to make sure that the resulting mixture does not cause phytoxicity or reduce the effect of the material.

General things to consider when mixing pesticides

- In the case of fertilizers, a mixing test must be performed because some of them dissolve better when first added to the tank and others vice versa when added at the end.

- It should be noted that acidic pesticides should not be mixed with alkaline pesticides and pesticides containing copper compounds should not be mixed with other pesticides. However, mixing pesticides with sulfur compounds with other pesticides and mixing insecticides with fungicides and herbicides is also not a good practice.

- Avoid mixing insecticides that have the same function or are in the same chemical group, and in terms of resistance management, if an insect is resistant to an insecticide, mixing with a pesticide from the same group will create cross-resistance to the second compound. Because mixing these two compounds increases the selective pressure on the pest. For example, carbamates and organophosphates have the same action on pests, and pyrethroids and DDT have the same cross-resistance.

- Infinito fungicide cannot be mixed with copper compounds and mono- element fertilizers containing heavy elements with calcium fertilizers.

- Hormonal herbicides such as 2.4.D cannot be mixed with any of the herbicides. But Granstar herbicide can be mixed with grass leaf herbicides such as Topic and Puma Super.

Tips on mixing fertilizers

Some fertilizers tend to form insoluble compounds and sediments. Sediments separate nutrients and prevent them from being absorbed by the plant or clog irrigation systems. For example, calcium fertilizers should not be mixed with sulfate and phosphate fertilizers.